Auto parts with weather resistance, high temperature resistance, high strength, high stability and compliance with environmental regulations

Plastics in automotive manufacturing have a wide range of applications, characterized by:

Lightweight: Plastics are generally lighter than metal, contributing to a reduction in the overall weight of vehicles. Lightweight construction helps improve fuel efficiency, reduce energy consumption, and enhance vehicle performance.

Versatility in Shape: The flexible production process of plastic allows for the creation of various complex shapes and structures, contributing to greater design freedom.

Corrosion Resistance: Plastics are less susceptible to corrosion compared to metal materials, making vehicles more durable in harsh environmental conditions.

Sound and Thermal Insulation: Some plastic materials exhibit excellent sound and thermal insulation properties, contributing to increased comfort in the vehicle by reducing noise and minimizing heat transfer.

Wear Resistance: Certain specialized plastic materials have outstanding wear resistance, suitable for both interior and exterior components, such as interior decorations and exterior accessories.

Impact Resistance: Some plastic materials offer superior impact resistance, contributing to enhanced vehicle safety.

Cost-Effectiveness: Plastics are generally more cost-effective than metals, helping to lower the manufacturing costs of vehicles. Additionally, the production process for plastics is relatively economically efficient.

Recyclability: Some plastic materials are highly recyclable, aiding in reducing environmental impact and aligning with the modern automotive industry's emphasis on sustainability and environmental friendliness.

Protective Performance: High-strength plastic materials with superior impact-absorbing capabilities provide better safety performance for vehicles.

Related Introduction:

>> Challenge the Limits of Flight with Innovative PA Nylon Carbon Fiber Composite Material!

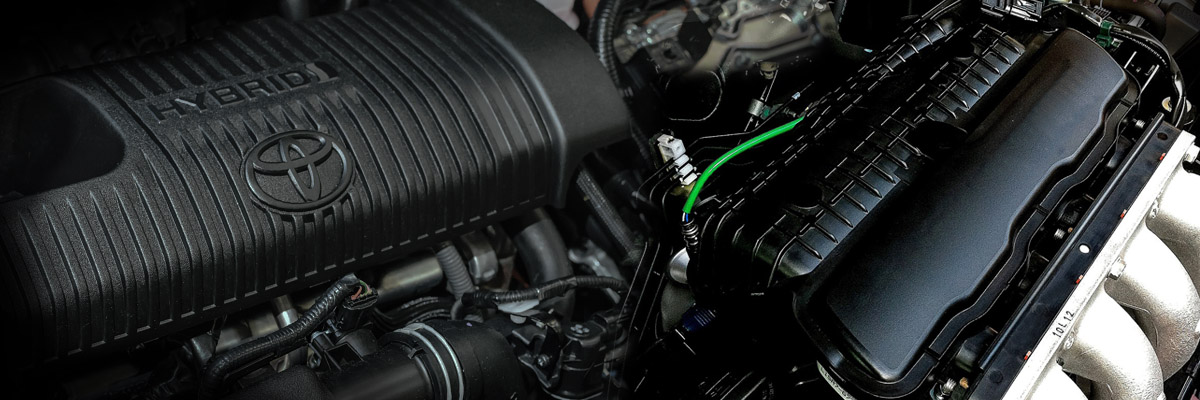

Here are examples of automotive components that may use various plastic materials, including but not limited to PP, ABS, PC, PE, PA, PU, etc. Please note that the actual materials used may vary depending on the vehicle model, manufacturer, and style:

Engine compartment bracket (PP)

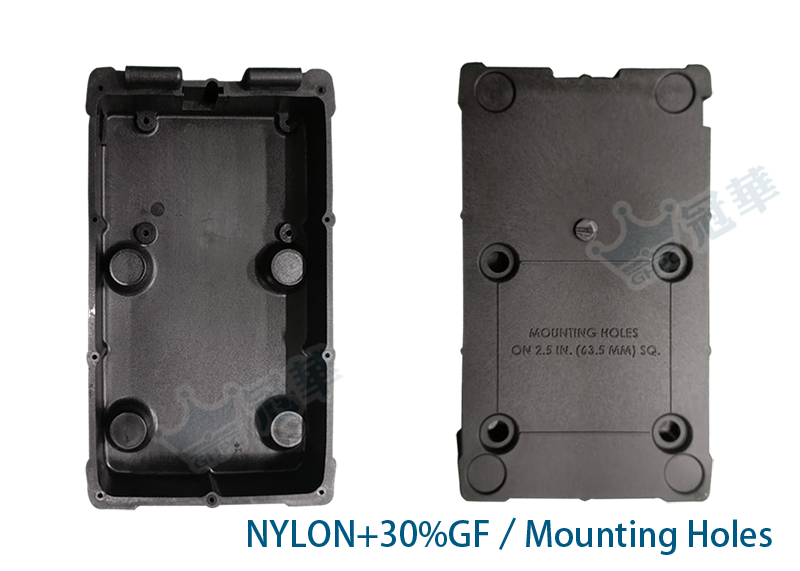

Engine compartment wiring fixed seat (PA66)

Engine compartment connecting pipe clamp (PP)

Engine compartment connecting pipe clamp fixture (PP)

Engine compartment connector (PA66)

Engine compartment heat shield (PPS)

Engine compartment cover plate (ABS)

Engine compartment shielding plate fixed seat (PP)

Steering wheel connector (PA6)

Steering wheel cover (PU)

Steering wheel adjuster gear (PA6)

Door interior handle (ABS)

Door interior panel (ABS)

Door window frame fixing clamp (ABS)

Door guide plate (ABS)

Window lifting system connector (PBT)

Window lifting system gear (POM)

Chassis connecting rod fixture (PP)

Chassis suspension link (PP)

Chassis suspension component (PA66)

Air filter fixed seat (PP)

Air conditioning system fixed seat (PP)

Air conditioning system pulley (PC)

Air conditioning system flywheel (PC)

Air conditioning panel (PC)

Air conditioning vent (PP)

Seat belt buckle (PBT)

Seat slide rail (HDPE)

Seat slide rail fixed seat (HDPE)

Seat slide rail fixed seat (PP)

Seat adjuster gear (PA)

Exhaust system suspension bracket (PA66)

Exhaust pipe bracket (PA66)

Exhaust pipe fixed clamp (PA6)

Fuel system connecting pipe clamp (PA66)

Fuel system connector (PA66)

Fuel tank (HDPE)

Fuel tank connecting pipe clamp (PA66)

<Actual applications may vary depending on the vehicle model and manufacturer.>

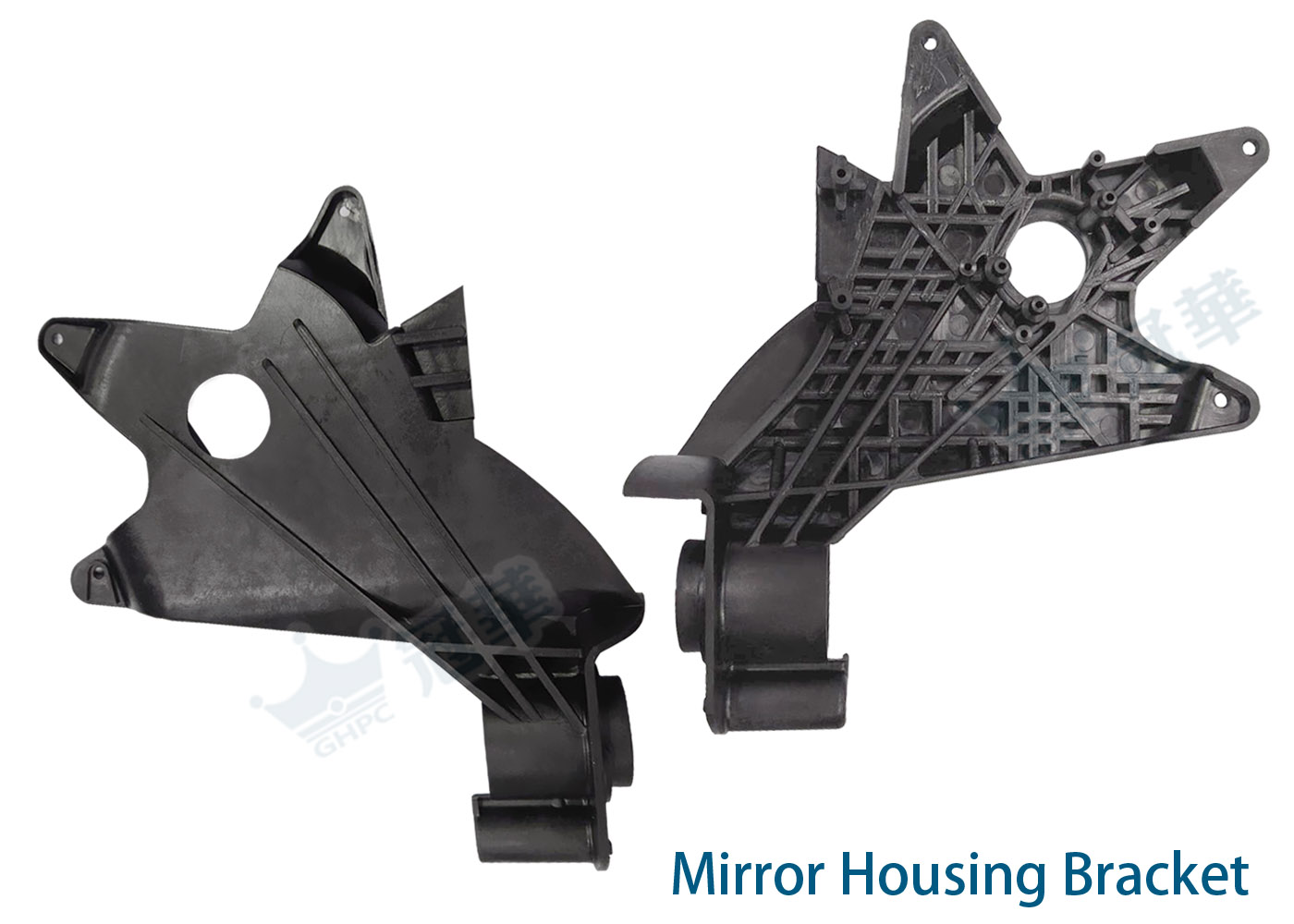

Automotive interior and exterior trims, instrument panel shells, cup holders, inner lamp housings, fasteners, end plugs, inner boxes, interior buttons, auto and motorcycle accessories, automotive engine room accessories, engine accessories, automotive electrical accessories, water tanks, automotive chassis parts , Motorcycle internal parts and rear armrest frame, automobile filter housing, fan, lamp reflector, electroplating grade nylon, lamp housing base, rearview mirror seat, etc.

Interior components, instrument panel casing, interior buttons

▌Recommended Products

GHPC PA6|Rigidity,Wear resistant,|

Bearings and other movable products, pedal covers, automobile engine compartment accessories and exterior parts, motorcycle glove boxes, motorcycle rear seat armrests, electric tool casings and parts, motor casings, electric tool casings, automobile and motorcycle accessories, electric tool casings , automatic sprinklers, heavy machinery handrails, electroplating grade nylon, lamp housing bases, rearview mirrors, power connectors, switch sockets, motor spools, nylon wave tubes, belts, large injection molding parts, automotive interior parts, industrial plugs and sockets , wheels, automotive interior and exterior parts, electronic appliances, machinery industry, locomotive spare parts...

▌Glass fiber reinforced and impact resistance PA6

More Nylon6...

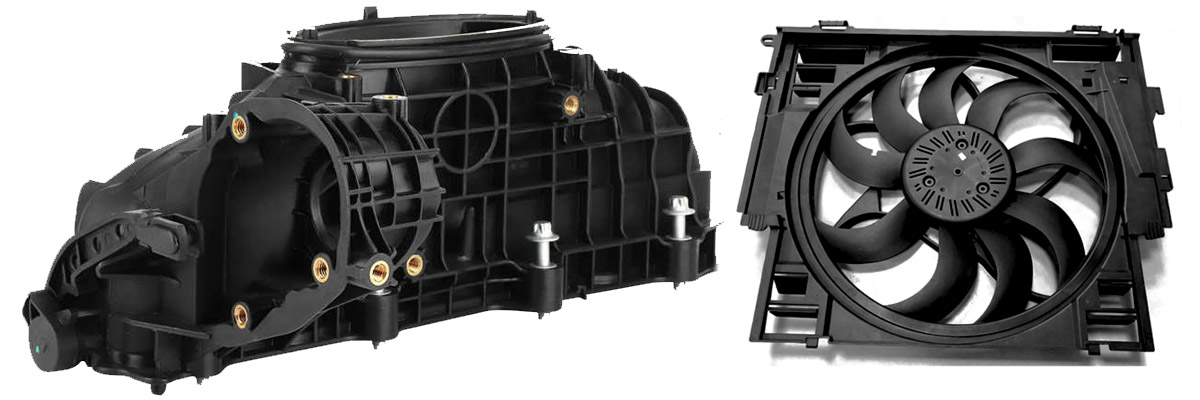

Engine cover, controller, connectors, water tank casing, water cooling fan blades...

▌Recommended Products

GHPC PA66 |Nylon 66 resin is an engineering plastic with higher melting point |

Automobile engine parts, water tanks, exhaust fans, locomotive parts, mechanical components, electronic components, industrial components, reels, cable switches, wrench tools, auto parts, electric tool shells, power switches, power plugs, electronic connections Devices, electronic parts, automotive interior parts, hand tool housings, fans, door handles, filters, conveyor belts, bearings...

▌Glass fiber reinforced and impact resistance PA66

Motorcycle parts, motorcycle storage boxes, motorcycle rear seat armrests, light housing bases...

▌Recommended Products

TORAY【TORELINA™】PPS|Oil resistance, high temperature resistance, chemical resistance|

Motor casings, pump wheels, gears, pulleys, universal heads, gaskets, flanges, counters, levels, flow meter components, compressors and pump components, valves, sliding bearings, chain guides and base plates, DC sensors Motors, gearboxes, coreless motors, stepper motors, internal rotation brushless motors, external rotation brushless motors, pump motors, vibration motors.

US NSF certification

▌Non-Enhanced PPS

Dashboard casing, car buttons...

▌Glass fiber reinforced PPS

Engine room upper cover, pipelines, water tank shell...

▌Recommended Products

PP Composite Material|High rigidity、Good heat resistance、Toughness reinforced|

Automobiles, electrical appliances, sports equipment, machinery industry, office chair handles

▌Glass fiber reinforced PP

More PP...

Blower wheel, cooling fan, water cooling fan...

▌Mineral fiber reinforced PP

More PP...

Car rearview mirrors, car light housings...

▌Mineral fiber reinforced and impact resistance PP

car dashboard